KM50-C

Smart Power Monitor

Power and current can be measured simultaneously. Measurement of generated power (regenerative power), leading reactive power, lagging reactive power, and consumed power. Low Cost Power Monitor.

last update: December 3, 2014

Functions That Support Energy-saving Analysis

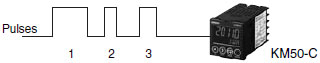

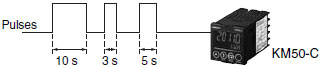

Pulse Measurement and Conversion

To support energy-saving analysis, power consumption can be compared with the flow rate of air, gas, or other

fluids with a single Unit.

The consumption rate of a device can be measured by dividing the power consumption with the measured number

of operations or operation time.

Pulse Input Count Measurement

Pulse Input ON Time Measurement

Simple Temperature Measurement

KM50 Power Monitors have a thermistor chip built onto the panel surface for easy measurement of the panel surface temperature.

The temperature display can be offset to match the room temperature to manage trends.

Energy Management with High-precision Measurements

Total Regenerated Energy Measurement

In addition to the consumed energy (total regenerative power consumption), generated power (total regenerative energy) can also be measured.

A single Power Monitor can measure equipment that effectively uses power generated by reverse motor rotation.

Total Reactive Power Measurement

In addition to instantaneous reactive power, the total leading or lagging power consumption can also be measured.

Together with peak power measurements, this function aids with monitoring the power distribution equipment.

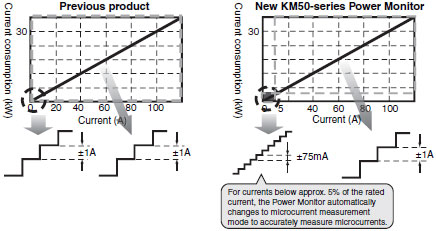

Automatic Range Switching

Automatic range switching enables high-accuracy measurements even for microcurrents.

Standby and stopped power can be accurately measured.

When measured at the distribution board, the total of the distributed values is almost the same as the base measurement.

You can measure microcurrents of ±75 mA with a CT with a rated current of 100 A. (Reference Value)

You can measure microcurrents of ±4 mA with a CT with a rated current of 5 A. (Reference Value)

Note: Reference values are typical values. Actual values may vary.

Inverter Compatibility

Measurements can be made on the primary side of an inverter.

Power consumption can be measured even after installing inverters which are widely used to save energy. This enables you to accurately grasp the effect obtained by introducing the inverter.

Functions That Support Saving Energy

Conversion to Monetary Cost

The total power consumption can be converted to the equivalent monetary cost.

Displaying the cost of the wasted energy can be used to support energy-saving measures.

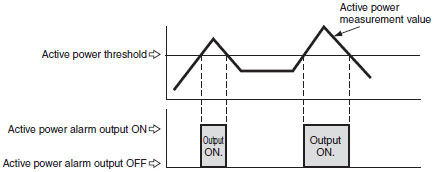

Alarm Output

An alarm can be output when active power exceeds a certain limit. There are two outputs; a pulse output and an output for alarm selection.

Alarms can also be set up for generated power (regenerative power), current, voltage, power factor, or reactive power to assist plant monitoring.

Built-in Logging Function

The total power consumption can be saved in internal memory every 5 minutes, hour, day, or month.

Data can be saved as follows: 5-minute data for two days, 1-hour data for eight days, 1-day data for month, and 1-month data for one year.

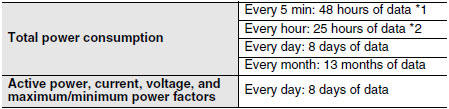

Data Logging Cycle and Amounts

Readout is not possible with key operations on the Power Monitor.

*2. Up to 48 hours of data can be read out using communications.

Functions That Support Installation and Settings

Simple Measurement

- The simple measurement function calculates the power from a fixed voltage and the measured current using a fixed power factor.

- This function can be used when the voltage cannot be input to the KM50 due to onsite conditions or wiring arrangements.

- If the Simple Measurement parameter is set to ON, the fixed voltage and fixed power factor can be set.

- The simple measurement function can be used to get an approximate power consumption of an installed circuit without wiring and measuring the voltage. Therefore, you must set the voltage and power factors to appropriate levels.

- Fixed values are used for the voltage and power factor, so the accuracy specifications do not apply.

Incorrect Wiring Detection

Incorrect voltage wiring can be detected.

If any mistakes were made during installation, they are automatically detected, reducing the time required for checking after installation.

This also reduces the risk of having to restart when a mistake is found.

Communications

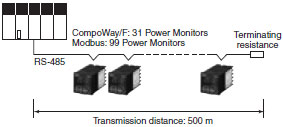

Up to 99 KM50 Power Monitors can be connected using RS-485 Modbus.

The energy use of each device can be managed with minimal wiring.

last update: December 3, 2014