R88M-G, R88D-GT

G-series AC Servomotors/Servo Drives with General-purpose Pulse-string or Analog Inputs

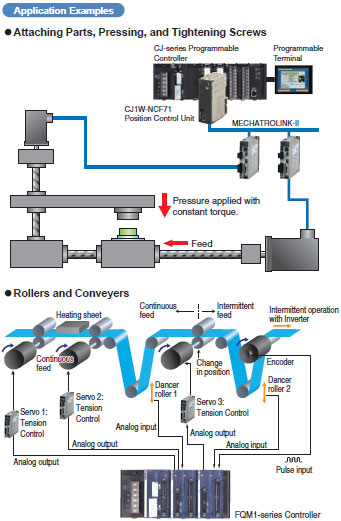

Support for a Wide Range of Applications with Position Control, Speed Control, Torque Control.

* Information in this page is a reference that you created on the basis of information in the product catalog before the end of production, may be different from the current situation, such as goods for / supported standards options / price / features of the product. Before using, please check the compatibility and safety system.

last update: December 16, 2013

Easy!

Easy Adjustment

Realtime autotuning sets the optimum gain.

An autotuning function calculates the device load in realtime and automatically sets the optimum gain, simplifying the adjustment procedure.

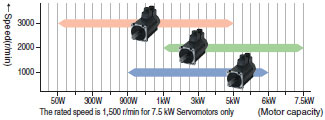

Select the Optimum Motor

A wide range of Servomotors is available to meet application needs.

You can select a suitable Servomotor from a wide range of Servomotor capacities to cater to various applications.

Reduce Control Panel Installation Space

Even Smaller Servo Drives.

The footprint of the Servo Drives has been reduced by 32% compared to previous OMRON models, helping to reduce control panel size.

Advanced Performance!

Reduce Tact Time

Significantly better speed response frequency.

The speed response frequency has been improved by a factor of 2.5 compared to previous OMRON models. The stabilization time has been reduced, increasing machine speed and response performance.

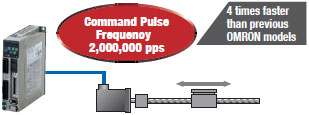

Reduce Tact Time

Fast positioning with improved command pulse frequency performance.

The command pulse frequency is 4 times faster than previous OMRON models. This enables fast, accurate control.

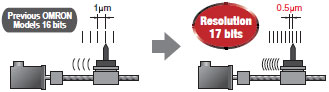

Improve Processing Accuracy

All Servomotors contain a 17-bit encoder*1 for greater accuracy.

Positioning is twice as accurate as previous OMRON models*2 for submicron accuracy. This enables stable control in the low speed range.

*1 For Servomotors with absolute encoders.

*2 Compared to previous OMRON models. (Servomotors with absolute encoders, 750 W max.)

Advanced Functionality!

Reduce Mechanical Vibration

Quick suppression of vibration with an adaptive filter.

Even if the resonant frequency changes, realtime evaluation automatically follows the changes to reduce the effect of vibration due to low mechanical rigidity, such as for conveyer belts.

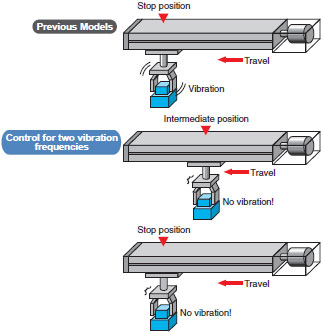

Reduce Tact Time

Reduce mechanical vibration with the vibration control function.

By removing the vibration frequency components between the stop position and the intermediate position, vibration that occurs due to low mechanical rigidity can be suppressed. (Control for two vibration frequencies)

Flexible Application

Change the command control mode as required by the application.

Select from position control, speed control, and torque control for use in applications such as the pressing, tension, and injection.

last update: December 16, 2013

Product Category

Product Category

Motion / Drives

Motion / Drives

-

Servomotors / Servo Drivers

Servomotors / Servo Drivers

-

Discontinued

- R88M-G, R88D-GT

-

Discontinued

-