K8DT-AS

Single-phase Current Relay

Our Value Design Products Increase the Value of Your Control Panels. Detect errors in motors and other equipment through current changes. Use in either overcurrent or undercurrent mode.

last update: January 22, 2024

For building green control panels

Natural disasters caused by global warming and climate change are became global social issue, that drives over 150 countries and regions worldwide to take action toward decarbonization. Our goal is to reduce greenhouse gas (GHG) emissions toward half by through new ways of building control panels, that key figure of the manufacturing site.

Integrating green perspectives into Value Design

Value Design for Panel (Value Design) is the common concept shared across OMRON’s in-panel product specifications to deliver new value to your control panels.

This Value Design also integrate environment consideration concept that enable earth and user-friendly control panel building.

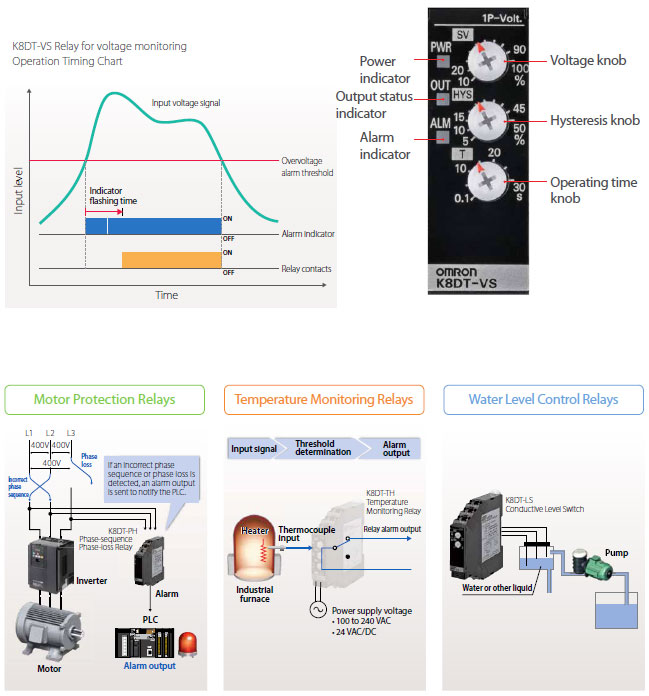

What Are K8DT Measuring and Monitoring Relays? These Relays function as alarms for which you can set a threshold value

[Input signal*] A voltage, current, temperature (thermocouple or platinum resistance thermometer), or water level

(electrode) can be input.

[Alarm output] You can select a relay or transistor output.

*There are different models for different inputs.

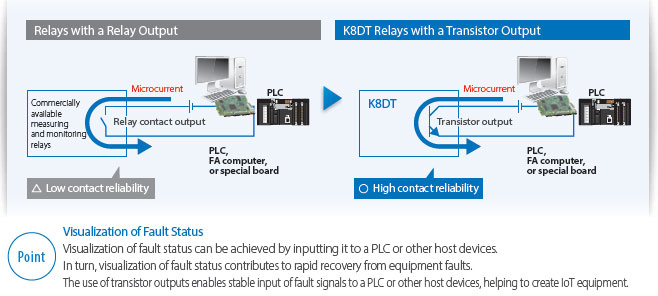

Long-term Contact Reliability Contributes to Visualization of Fault Status

Industry First*: Models with Transistor Outputs

*According to OMRON investigation in November 2015.

Use transistor outputs to take advantage of the long-term contact reliability.

The operating frequency of Measuring and Monitoring Relays is low, which means the surfaces of relay contacts can deteriorate and reduces reliability. Particularly for microcomputer board and PLC inputs, a microcurrent of 5 mA or less for switching reliability is required, making transistor outputs superior.

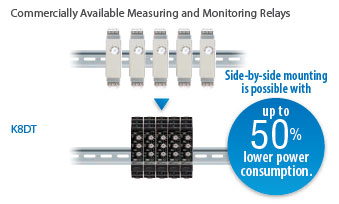

Low Power Consumption Design Enables Side-by-side Mounting

The power consumption has been greatly reduced in comparison with commercially available measuring and monitoring relays.

A lower power consumption means that internal heat generation is suppressed, which enables side-by-side mounting.

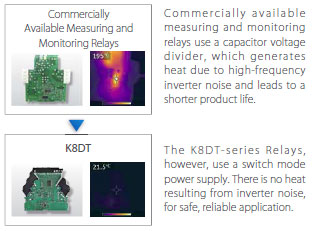

Reliability Even in Poor Noise Environments

There is no heat generated by high-frequency noise, which enhances reliability.

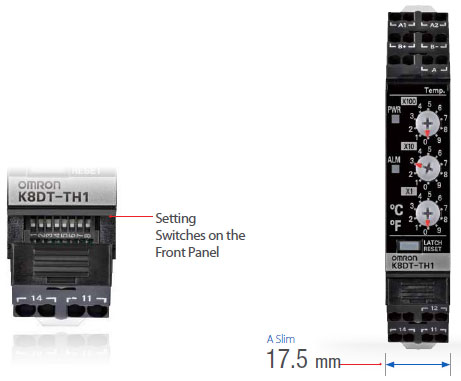

Control Panel Downsizing and Reduced Wiring; Flexible Layout with a 17.5-mm Width

This Is the Shape That Resulted from Efforts to Downsize Panels and Reduce Wiring.

• The slim body is only 17.5 mm wide to enable control panel downsizing.

• To simplify wiring, Push-In Plus terminal blocks are positioned at the front.

• To simplify changing settings, the setting switches were placed on the front.

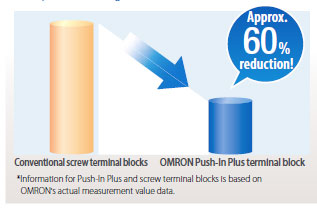

Push-In Plus Terminal Blocks for Easy Wiring

Just Insert Wires: No Tools Required Now you can use Push-In Plus terminal blocks to reduce the time and work involved in wiring.

Greatly Reduce Wiring Work with Push-In Plus Terminal Blocks

*Information for Push-In Plus and screw terminal blocks is based on OMRON's actual measurement value data.

Wiring Possible with Stranded Wires

You can insert wires with pin terminals or ferrules, or you can also insert solid wires or stranded wires.

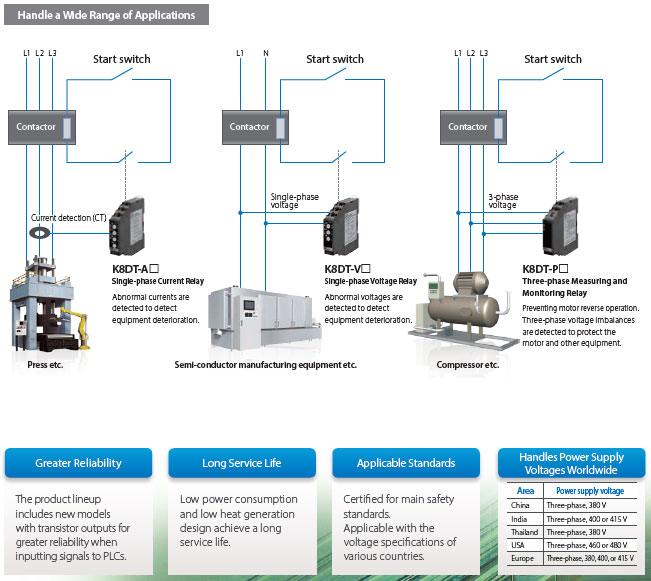

Application Examples:

Motor Protection

K8DT-A[]/-V[]/-P[]

[Application] Ideal for monitoring for error trends in motors and other equipment

(e.g., equipment with three-phase motors, expensive equipment, and equipment with compressors).

[Features] High reliability for worry-free application.

last update: January 22, 2024