S8VK-X

Switch Mode Power Supply (60/120/240/480-W Models)

EtherNet/IP, Modbus TCP-Compatible Maximizing System Availability Through the Connecting of Equipment to IoT

last update: November 8, 2021

A new style of facility maintenance brought about by the visualization of power supplies

Visualizing and centrally controlling the condition of power supplies enables you to systematize equipment maintenance before equipment trouble occurs, eliminating unexpected response and unnecessary premature replacement, and thus reducing the overall maintenance cost.

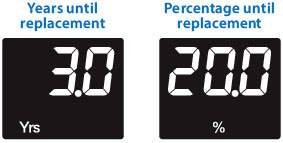

The first step in scheduled maintenance: visualization of the time to replace power supplies.

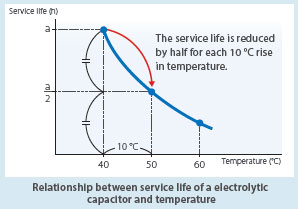

S8VK-X calculates the deterioration of the internal electrolytic capacitor based on its component's temperature. It is indicated on the display as well as via the communications system.

[Do you know?] A power supply has a service life.

In general, aged deterioration of the internal electrolytic capacitor degrades the original performance (service life) of a power supply and ceases to function in the end. Using a power supply close to its service life may cause a disruption of output voltage even at power-on state and unexpected shutdown of equipment.

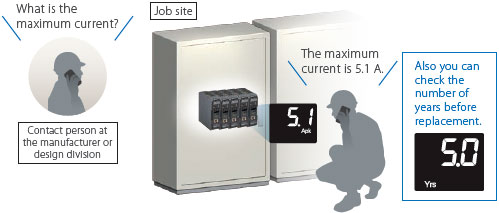

Furthermore, voltage, current and maximum current can be displayed; More and more useful in various applications.

Advantages during design and measurement

You can easily check the expected output voltage and the designed current (steady-state and maximum) without using measuring equipment.

Advantages during operation

You can check the output voltage and current of power supplies on site without using a tester.

You can also check the maximum current value.

Advantages during malfunction and maintenance

You can report and give commands, while checking the output voltage and current by operating the monitor without using a tester.

Why don’t you change your power supply to S8VK-X to achieve a new style of facility maintenance?

World’s smallest class*1 of power supplies with a communication function

The space-saving design enables you to mount side-by-side and replace conventional power supplies in a control panel smoothly.

*1. According to OMRON investigation in October 2017.

*2. Two units of S8VK-X 240 W and W4S1-05D Switching Hub

Excellent environmental resistance contributes to the stable operation of equipment

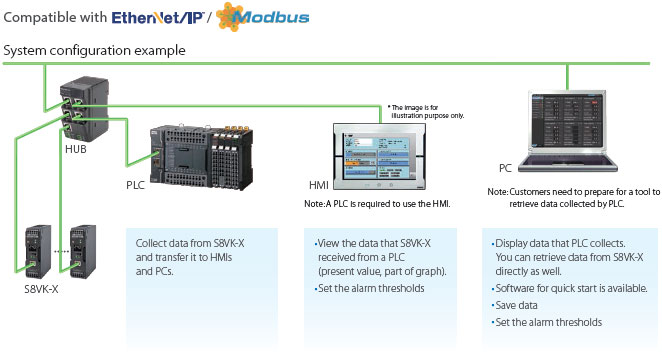

Compatible with the communication methods used globally in a variety of applications

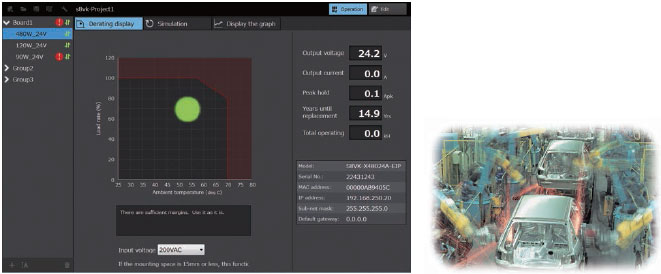

Starting product monitoring is easy with the free “Power Supply Monitoring Tool” software

By using the Power Supply Monitoring Tool, it is possible to start monitoring by simply connecting the S8VK-X to a personal computer via an Ethernet cable. In addition to collectively displaying and saving data and displaying graphs, it is also possible to check the status in real time on a derating chart and to simulate of capacity changes.

What you can do with Power Supply Monitoring Tool

Collective display of data, saving data, and the alarm display

It is possible to collectively monitor up to 18 power supplies in multiple locations in real time. It is also possible to conduct feedback on the status to take the appropriate action at the appropriate time and to improve the accuracy of maintenance plans.

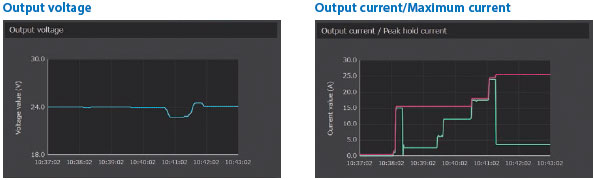

Voltage and current graph displays

Continuous data monitoring is possible without adding extra devices such as clamp meters and data loggers.

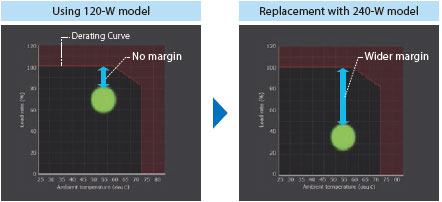

[World’s first*] Usage status check and simulations

*According to OMRON investigation as of March 2018.

It is possible to check the status of power supply usage in real time on a derating chart and to identify risks.

Unexpected equipment shutdowns can be prevented by appropriate maintenance beforehand.

This contributes to the realization of equipment that does not stop and improves facility operating rates

[Example use]

• It is possible to simulate the margin that would be created if the product currently in use is replaced with a type with a larger capacity.

• It is possible to check how the margin (the existence of risk) on the power supply is affected by changes in the surrounding environment, such as between daytime and nighttime and in different seasons.

last update: November 8, 2021