Industrial Automation

Industrial Automation

A leading contact lens manufacturer in Asia supplies high-quality medical products to a global market. Operating in a highly regulated industry, the manufacturer must ensure consistent quality, full inspection coverage, and strict compliance—while maintaining high throughput in a competitive, high-volume production environment.

As production volumes increased, the manufacturer faced growing challenges in its final inspection process for contact lens packaging. Inspection involved verifying multiple parameters, including blister integrity, lens positioning, and label accuracy. These checks were critical to ensuring product safety, regulatory compliance, and brand reputation.

However, the inspection process relied heavily on manual visual checks. Under high-speed production conditions, this approach proved to be slow, inconsistent, and prone to human error. Inspector fatigue and subjective judgement led to a 20% defect rate, creating quality risks and rework.

To maintain inspection coverage, the manufacturer required 12 inspectors across three production lines, resulting in high labour costs and limited scalability. Despite the manpower investment, manual inspection could not guarantee consistent, repeatable results—especially as product variation increased.

The manufacturer needed a solution that could:

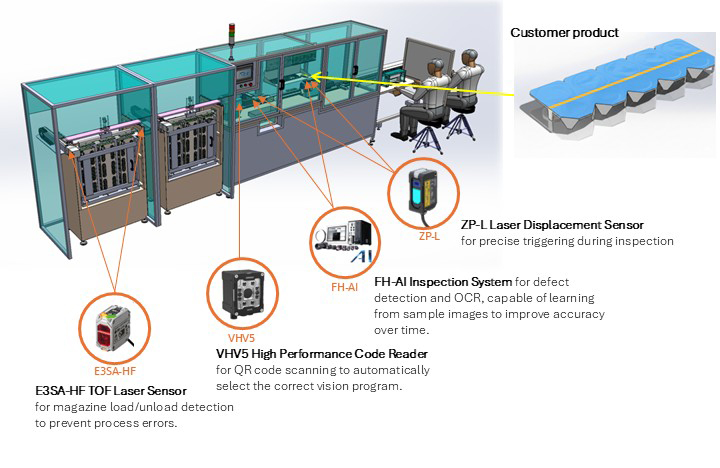

To address these challenges, the manufacturer partnered with Omron to implement an AI-powered vision inspection system centered on the FH Series AI Vision (FH-AI) platform.

The solution replaced subjective manual checks with high-speed, objective, and repeatable inspection, ensuring stable quality regardless of operator or production conditions.

Key Solution Components

FH-AI Defect Detection and Optical Code Reading

Unlike conventional vision systems, the FH-AI solution required significantly less setup and tuning time. The AI learning process was completed in hours instead of weeks, allowing the customer to move quickly from proof of concept to deployment.

The implementation delivered immediate and measurable improvements across quality, productivity, and cost.

Customer reference

EN | PDF 3MB

COPYRIGHT 2024 @ OMRON CORPORATION. ALL RIGHTS RESERVED.

| Cookie | Duration | Description |

|---|---|---|

| cookielawinfo-checbox-analytics | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Analytics". |

| cookielawinfo-checbox-functional | 11 months | The cookie is set by GDPR cookie consent to record the user consent for the cookies in the category "Functional". |

| cookielawinfo-checbox-others | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Other. |

| cookielawinfo-checkbox-necessary | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookies is used to store the user consent for the cookies in the category "Necessary". |

| cookielawinfo-checkbox-performance | 11 months | This cookie is set by GDPR Cookie Consent plugin. The cookie is used to store the user consent for the cookies in the category "Performance". |

| viewed_cookie_policy | 11 months | The cookie is set by the GDPR Cookie Consent plugin and is used to store whether or not user has consented to the use of cookies. It does not store any personal data. |