E2E NEXT

Proximity Sensor

Enables easier and standardized designs previously not possible. IO-Link as a standard feature

last update: January 5, 2023

Easy design

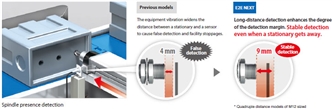

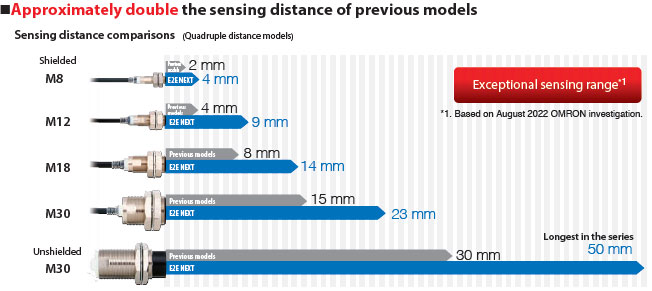

Equipped with exceptional sensing range*1 to enable collision-free sensor installation

Enables designs with more distance between the sensor and the sensing object, thereby reducing unexpected facility stoppages due to collision and false detection, which occurred with previous proximity sensors.

*1. Based on August 2022 OMRON investigation.

Allows for more spacious design with less risk of contact

With previous models, to avoid false detections, you were forced to adopt sensor installation designs that risked contact. The E2E NEXT PREMIUM Proximity Sensor can detect accurately from a greater distance, which means you can adopt designs with more space and less risk of contact.

Less false detection even when a stationary gets away from the sensor due to equipment vibration

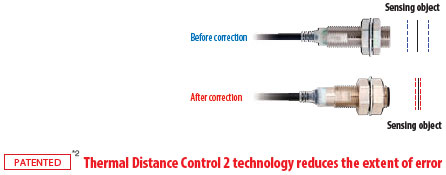

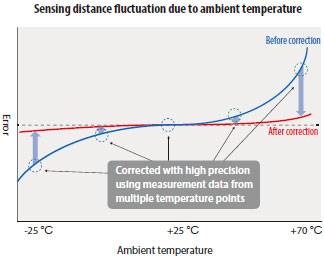

PROX3 hybrid circuitry with Thermal Distance Control 2 eliminates ambient temperature influence to enable extended sensing ranges.

Proximity sensors with longer sensing distance require increased sensitivity. However, with the increased sensitivity, temperature changes will have bigger influence in sensing distance, and differences between individual sensors will be bigger. E2E NEXT Proximity Sensors (3-wire models) solve these issues by newly implementing Thermal Distance Control 2, a technology to enable extended sensing ranges. It enables in-line measurements of each sensor’s temperature characteristics, using multiple temperature points, in IoT-enabled production processes. The optimal correction values are then calculated based on our unique algorithm. The values are written into the analog digital hybrid IC (PROX3) for shipping to minimize differences between sensors and the influence of temperature changes that may occur in the customer’s environments.

Japan. (As of September 2022)

Standardized design [PREMIUM Model]

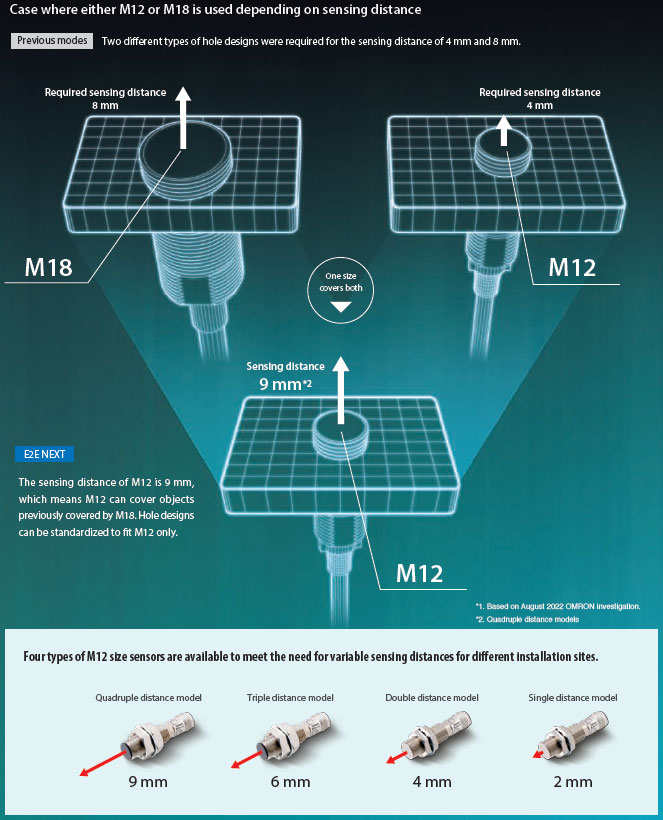

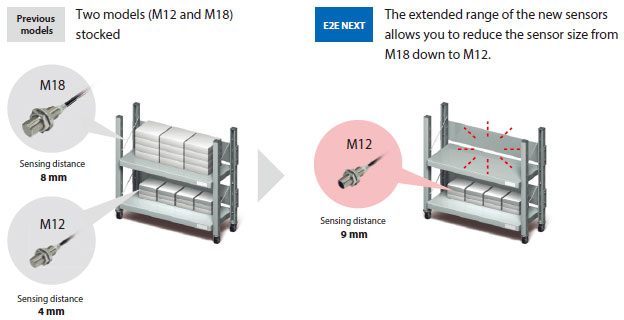

Exceptional sensing range*1 allows you to standardize your design with a single one-size model

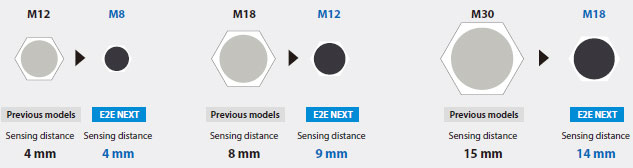

Ensures equivalent sensing distance while being one size smaller than previous models. Equipment and facilities formerly designed to use sensors of multiple sizes can now be designed to use sensors that are all the same size, allowing you to standardize your designs.

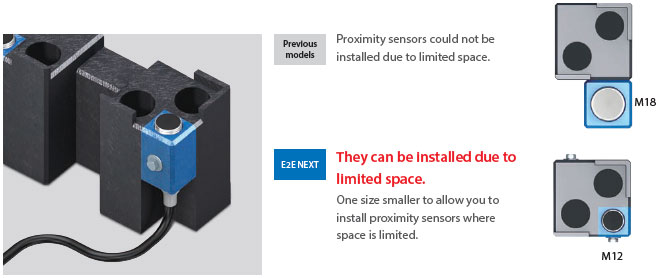

Easy to install, even where space is limited

E2E NEXT PREMIUM Model Proximity Sensors ensure equivalent sensing distance while being one size smaller than previous models, allowing you to install them in spaces where conventional sensors were too big to fit.

Note: When installing proximity sensors, make sure to factor the influence of surrounding metal into your designs.

(Refer to Influence of Surrounding Metal upon Design on Catalog for details.)

One size smaller than previous models

Size comparisons between models with equivalent sensing distance (“E2E NEXT” refers to quadruple distance models)

Unifying the model types to reduce the number of parts kept in inventory.

New standards for usability Early error detection [PREMIUM Model] [BASIC Model]

Enables facility designs that allow for early discovery of the site and substance of failure

Less time required from failure to recovery (MTTR: Mean Time To Recovery).

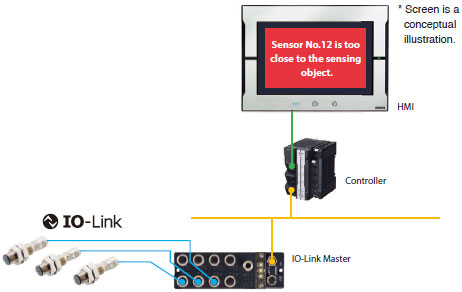

Enables real-time identification of the site and substance of sensor failure from a single location

By using the IO-Link Master to connect proximity sensors to your controller, you can use your monitor (HMI) for early discovery of the site and substance of proximity sensor failures.

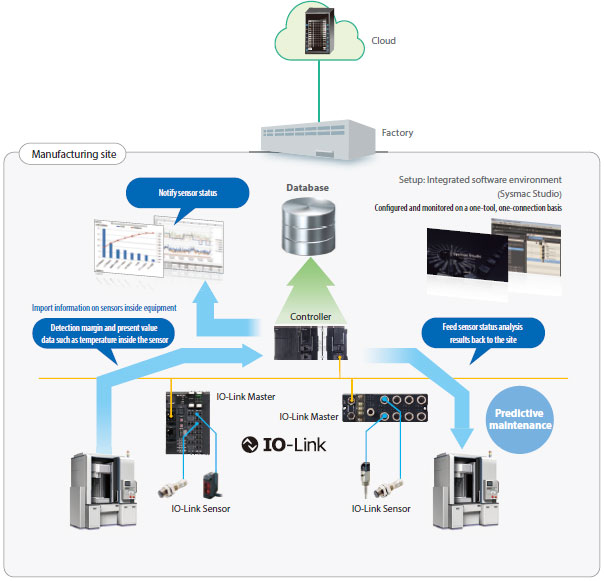

Enables predictive maintenance through condition monitoring

Connecting sensors with controllers using IO-Link Master enables to send information necessary for stable operation to host devices. This enables condition monitoring and failure detection of sensors, which in turn contribute to predictive maintenance of equipment and facilities. You can also increase the productivity of your facility by accumulating information in databases and feeding analysis results back to equipment on the site.

New standards for usability Quick recovery [PREMIUM Model] [BASIC Model]

* Applies only to the description of the high-brightness LED indicator.

Enables facility designs that allow for quick recovery in case of failure

Less time required from failure to recovery (MTTR: Mean Time To Recovery).

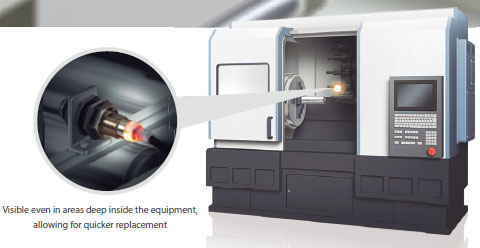

All around visible high-brightness LED indicator

Adopts high-brightness LED that is more luminous and visible than those in previous models. The indicator is visible from all angles, reducing the time required for operation checks after sensor replacement.

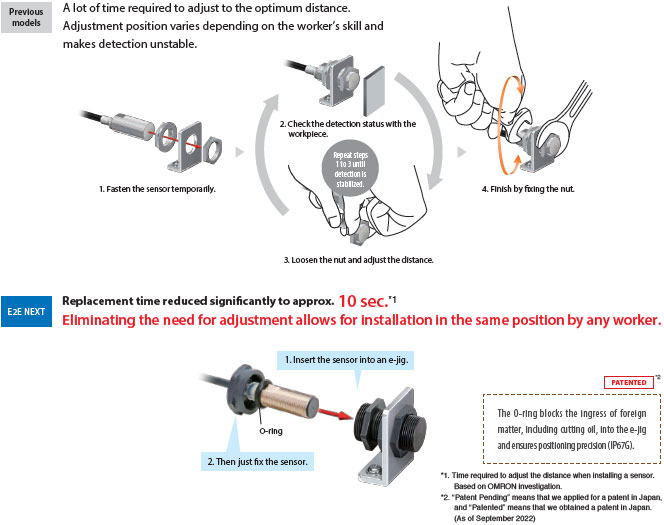

Replacements in as little as 10 seconds*1 using e-jig

Using e-jig eliminates the need for adjustment so that anyone can install in the same position.

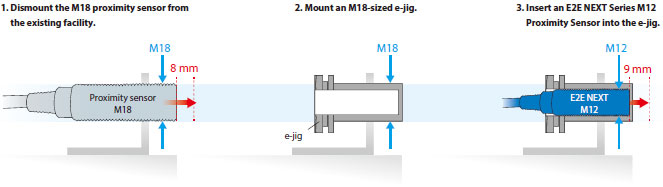

Easily upgrade existing facilities to enable “10-second* proximity sensor replacements”

The HIGH SPEC Model’s sensing distance is approximately twice that of previous models. For example, the sensing distance of the quadruple distance model of M12 sized is 9 mm, which is about the same as conventional M18 models. Using these sensors together with the e-jig allows you to easily upgrade your existing facilities so that you can replace their sensors in just 10 seconds.*1

New standards for usability Less unexpected facility stoppages [PREMIUM Model] [BASIC Model]

Excellent environmental resistance enables robust facility design

Reduces sudden facility stoppages by reducing the number of failures, even in severe environments.

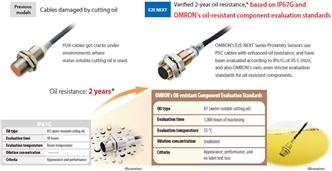

Cables with enhanced oil resistance shut out cutting oil for 2 years*1

Our new PVC compound protects against damage caused by swelling, deterioration or cracking, preventing oil from seeping into and destroying internal circuits. Designed to resist oil ingress for up to two years.

Two years*1 of stable operation verified by OMRON’s unique evaluation technology

Two years*1 of stable operation verified for pre-wired connector models as well, using similar oil resistance tests

• Delivers 2-year oil resistance*1 by adopting technologies unique to OMRON and PVC cables with enhanced oil resistance. [PATENTED]*2

• Smartclick connector cables block the ingress of cutting oil, and with the same torque, no matter who connects them.

For machining processes where the amount of splashing cutting oil is large, oil-resistant Proximity Sensors E2ER/E2ERZ

“2-year oil resistance” refers to median values (=Typical values) of the product designs and the oil-resistance

performance evaluation results.

Products to be shipped will have around 2 years of oil resistance; actual oil resistance will vary depending on the

product.

• The pre-wired connector model has a verified oil resistance of 2 years when mated with XS5 NEXT series round oil-

resistant connectors.

This value has not been verified for connector models(M1/M3/M5).

*2. “Patent Pending” means that we applied for a patent in Japan, and “Patented” means that we obtained a patent in

Japan. (As of September 2022)

IP69K compliant for water resistance and wash resistance

IEC 60529 compliant. Ensures water resistance during hot pressure washing, where equipment is washed intensively with high-pressure water or steam. (8,000 to 10,000 kPa pressure, 80°C hot water, 30 seconds for each angle)

last update: January 5, 2023